Manufacture

A fabrication workshop rooted in know-how.

MULTI-MATERIAL FABRICATION & WORKSHOP KNOW-HOW (METAL, WOOD, COMPOSITES, RESINS, GLASS, CONCRETE, CERAMICS, TEXTILES, ETC.)

TECHNICAL DEVELOPMENT & ADJUSTMENTS WITH CREATORS

MODELS, PROTOTYPES & MATERIAL TESTS

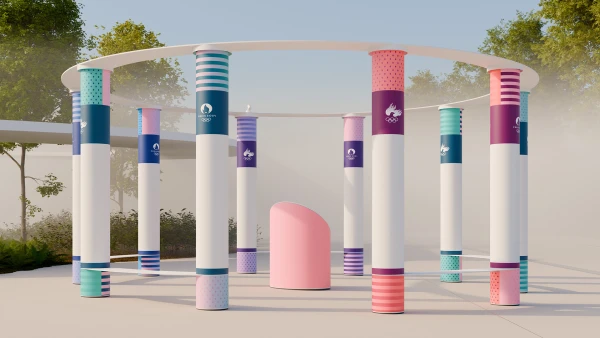

FULL-SCALE PRE-ASSEMBLIES & WORKSHOP VALIDATIONS (FORMS, TEXTURES, TONES, ASSEMBLIES)

SHAPING TECHNIQUES: METALWORK, JOINERY, MOULDING, LAMINATION, COMPLEX ASSEMBLIES

SUPERVISION OF DIGITAL MACHINING & CUTTING CARRIED OUT BY SPECIALISED PARTNERS (CNC, LASER, WATERJET, 3D PRINTING, 3D SCANNING) — COORDINATED & QUALITY-CHECKED BY CHD

SUPERVISION OF INDUSTRIAL FINISHES (POWDER COATING, VARNISHES, SURFACE TREATMENTS) IN COLLABORATION WITH CERTIFIED WORKSHOPS

TECHNICAL DOCUMENTATION, MARKING & LOGISTICS PREPARATION

COORDINATION WITH SPECIALISED PARTNERS DEPENDING ON PROJECT NEEDS

We give form to ideas: artistic engineering combining workshop skills, material expertise and fabrication precision.

Creating starts with seeing the artwork as a whole, then sculpting every detail. For over 25 years, CHD ART MAKER has been bringing creators’ visions to life as artworks, combining technical precision, exacting aesthetic standards and a workshop spirit.

Our work: fabricating unique artworks — sculptures, artistic or architectural installations — from prototypes to small moulded series, at every scale, combining artisanal know-how and digital technologies.

Copyright © Sheila Marshall

We work in close dialogue with creators and project owners.

Material tests, texture and colour trials, adjustments of forms and assemblies. This project-based support allows us to advise, research and validate choices at the right time, and to ensure coherence between 3D modelling, mock-up, expected rendering and technical constraints.

In Montpellier, our workshop brings together a composites and resins laboratory (masters, moulds, castings), metal and wood areas, and a modular assembly floor where we build and pre-assemble artworks, test volumes, adjustments, textures and colours, and validate choices with creators before shipment.

A long-standing network of specialised partners — machining, CNC cutting, steelwork, powder-coating, surface treatments, logistics — completes this setup and enables us to adapt production capacity to project complexity. Artworks are then prepared to travel: packing, marking, technical documentation and coordination of logistics in France and abroad.

Awarded the “Entreprise du Patrimoine Vivant” (EPV — France’s Living Heritage Label) since 2018, renewed in 2025, our workshop upholds a vision of “making” in which the intelligence of the hand, artistic sensitivity and technical precision come together in the service of demanding projects.

Possible deliverables

Execution drawings, prototypes & material tests, quality controls & validations, material / finish specifications, fabrication progress photos, assembly manuals, packaging plan & transport recommendations.

Related projects

Other expertise

-

DIALOGUE WITH ARTIST / PROJECT OWNER

SITE & CONSTRAINTs ANALYSIS

FEASIBILITY & TECHNICAL SOLUTIONS -

SITE COORDINATION

INSTALLATION METHODS & SAFETY

LIFTING, FIXINGS & COMPLIANCE -

DIAGNOSTICS & PROTOCOLS

WORKSHOP / ON-SITE INTERVENTIONS

PRESERVATION & SECOND LIFE